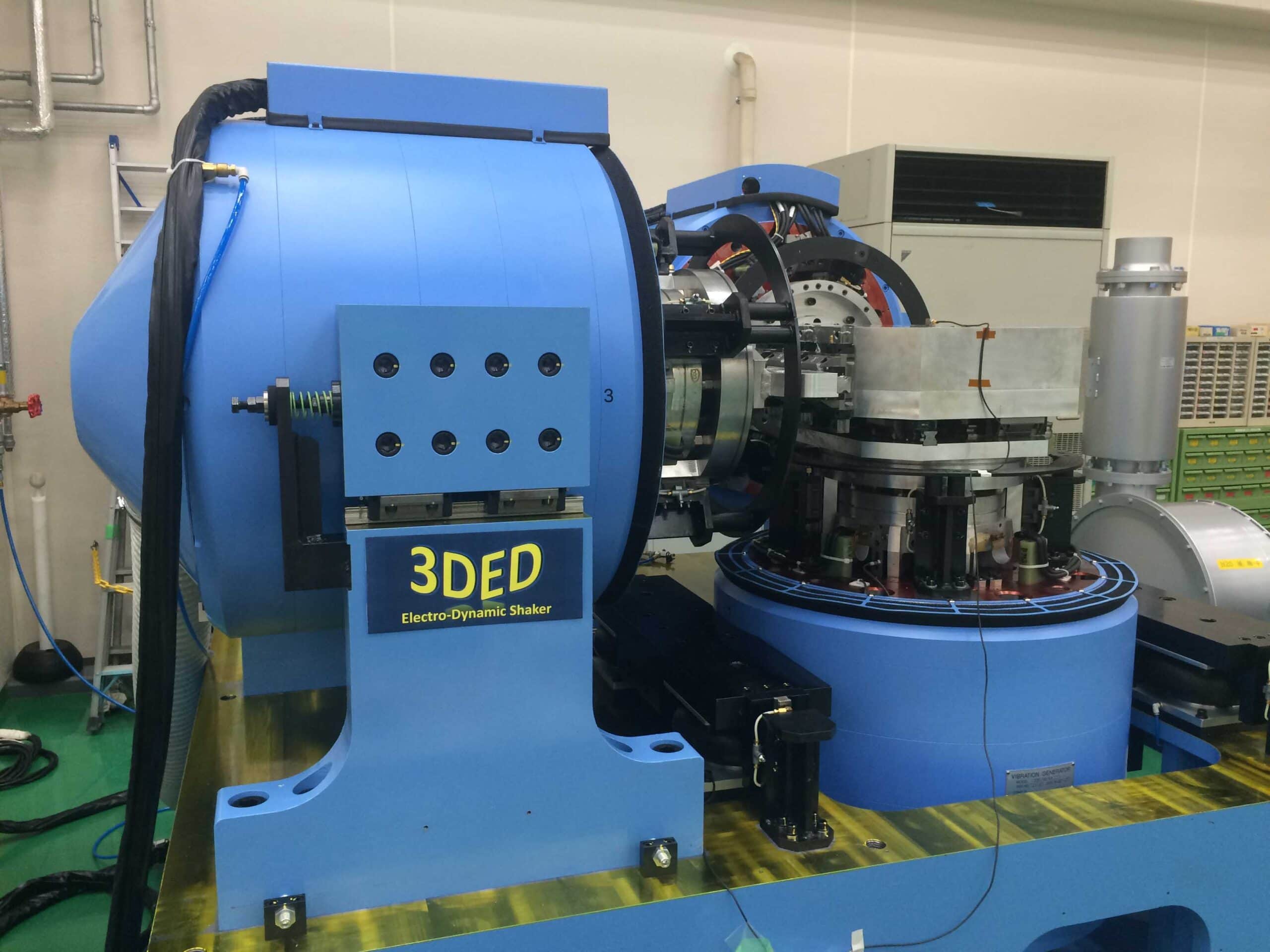

In response to our customers who love the Quake series of 3-Axis testing but want the same type of accuracy and reproducibility but with frequencies up to 2,000 Hz demand, Kokusai is now introducing a 3-Axis ED Shaker that actually meets MIL-STD-810 Standards. The Kokusai 3DED 3-Axis Simultaneous Electro-Dynamic Vibration Machine has a 5-2,000 Hz range with unparalleled response. Borrowing some of the patented technology from the Quake and with an additional 5 years of R&D effort, the 3DED™ has successfully achieved the difficult goal of maintaining key measurables at higher frequencies.

One of the keys was introduction of a unique multi-axis guide and structural support and alignment system (Patent: No. 2000-338010). Compared to hydrostatic support bearing systems which can be very expensive initially and also to maintain or replace, the 3DED™ utilizes a new support bearing system. It consists of both the slide system used on the Quake series as well as a completely new guide system that maintains structural integrity on the axis identified through the entire range of motions. Extensive testing and analyzation of the characteristics of causes and influences of inaccuracy and crossover affects were taken in all 3 axes simultaneously especially in the high frequency range. The slide system is both lightweight and highly accurate without having to deal with hydraulic fluids and seals. This 3 axis independent simultaneous slide system allows for full motion with minimal crossover effect. Additionally the horizontal and vertical guide system limits unwanted axis movement and increases Part Under Test capacity. With both isolation techniques the entire system limits any crossover, eliminating the need for an isolation pad.

Vibration/Impact Testers

Kokusai is proud to offer an extensive range of vibration and transportation testers – also called “shakers” – with applications in the aviation, aerospace, electrical, railroad, and trucking industries among many others. Our machinery has the ability to shake the smallest pharmaceutical vial all the way to an actual house to test earthquake readiness. The same foundational technology is used for each unit: a specialized electric servomotor actuator that can be configured according to customer needs into single, dual, or triple axis machines. This technology offers more accurate and reproducible results compared to servo-hydraulic machinery, as well as the ability to measure at much lower frequencies.

Multiple testing procedures are possible including vibration, free fall drop, compression testing, drop impact and side impact. Our machinery enables simulation of large acceleration impacts inside of a small footprint. Our four poster vibration tester simulates the super low displacement of road vibration, with 3 completely independent axes that have extremely low crossover residuals. This machine features automatic wheel base and tread base adjustment, and the ability to program each individual post with a different shaking profile including field waveforms, triangle, and random. G forces of up to 8Gs in the vertical and 5Gs in the horizontal are obtainable. Our machinery allows customers to closely mimic real world situations, with a large variety of scenarios. The highest standards are met with all of our equipment, including a full listing of JIS and ISO standards. As is the case with all of our machines, this equipment is available for full customization and integration into existing production methods. For more details about our available vibration and transportation testing machinery, or any of our other equipment and services, please see the table below or contact us directly.